Priming a diesel engine is the process of filling up the engine with the working fluid, i.e., diesel and removing the contaminants present in the diesel. Scroll down to find information on the priming procedure.

Priming is a process of cleaning and preparing an equipment before it is put into use. It is a very essential process to ensure the efficient working of a machine. Priming is also a process of injecting fuel into the fuel injection system or valve train of an engine. This process generally involves the same operating fluid to clean unwanted items from the machine. This means that if you want to prime a steam engine, it should be done with steam only. When it comes to diesel engine or any engine, fuel filters are mainly primed. This is because, the primary function of a fuel filter is to capture contaminants in the working fuel.

The information given below, will explain the process of priming, but please note that it is not for you to exercise it independently. It is just for you to understand the mechanism involved in the priming process. Priming should be done preferably by a mechanic as there are several complex situations involved in the process.

Priming a Diesel Engine

The term ‘diesel engine’ not only means that it works with a working fluid called ‘diesel’, but it also deals with a functional cycle called “diesel cycle”, i.e., a thermodynamic cycle explaining the energy transformations that take place during the working of such an engine. Such an engine is usually used in four wheelers and heavy trucks. The process of priming is very common in tractor engines. This is because, these engines are very susceptible to dust, water and other contaminants that affect the engine parts.

Priming of such an engine is to be done using diesel only. Avoid any other fluids to do it. However, it can also be done with alcohol, petrol and other liquids as well. The reason why we insist not to prime the engine with any fluid other than diesel is because, when diesel comes in contact with some other fluid it could produce some adverse effects during the working of the engine. So to avoid this, we use the same fluid as that of the working fluid to prime the engine.

Things Required

- Mechanic repair manual of the engine

- Wrench and screwdrivers

- Diesel

- Fuel filters

- Priming handle pump

Steps

Step 1: Before we start, find a good mechanic’s manual to know the machine well before you work on it. This is generally provided by the manufacturer, if not, you can get this from a nearby mechanic shop or you can even download it online. Once you gain some theoretical knowledge from the mechanic repair manual, it would be easy for you to apply it practically.

Step 2: Look for the supply valve in the fuel system and open it. On doing this, we are allowing the diesel to reach the engine.

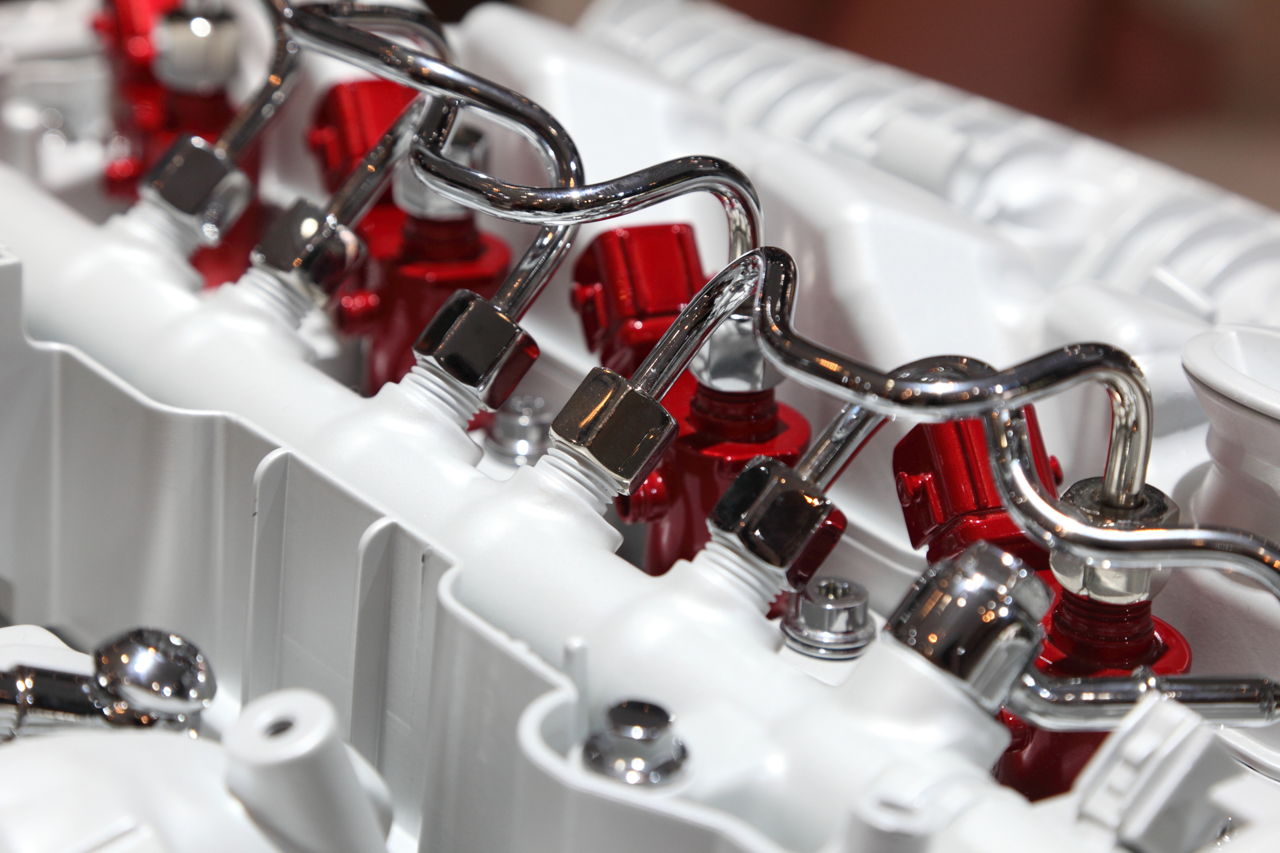

Step 3: Open the bleeder plug of the fuel filter and let all the air and diesel to evacuate from the system. Use a priming pump to force out the diesel and air bubbles present in the fuel filter. Do this process rigorously and repeat it until air bubbles stop coming out. Once it is done, close the bleed plug valve.

Step 4: Repeat the same process of priming in all the filters. If some filters are damaged, this is the right time to replace them. Don’t forget to mark the filters which are primed. Do it one by one.

Step 5: Now you can start the engine and run it in idle mode. During the start, it may not run smoothly, but once all the air bubbles are out, it will run smoothly.

This is not really an easy task to perform though it may seem to be easy. Priming is generally done after a seasonal change. Especially during summer, it may so happen that the fuel container gets empty and the engine starves for fuel which may cause malfunctioning of the engine. In such cases, priming is important. The high pressure circuit of these engine systems are generally designed to self prime. Self-priming takes place once the subsystem is primed.