Most cars today use an automatic transmission system, which makes the ‘Control Solenoid’ one of the most important components in it. Failure in the solenoid directly affects the running of the vehicle. This article explains the working and functioning of a modern-day transmission control solenoid.

Here’s a Tip

Keep inspecting the valve body every once in a while (without dismantling any parts) for leakages and burning smells. If any of the two seem to be taking place, carry out a repair or replacement for the solenoid right away!

Transmission control solenoids are found in vehicles or transmission units with automatic or electrically controlled transmission systems for shifting speeds. It is found in most modern-day vehicles, because of its accuracy and consistency in functioning.

The solenoid enables smooth shifting of gears to transmit appropriate speed and torque from the engine to the wheels. A defective solenoid may cause problems like shifting into the wrong gear, or not shifting at all. It directly affects the engine performance, as the load taken by it is dependent on the transmission module of the vehicle.

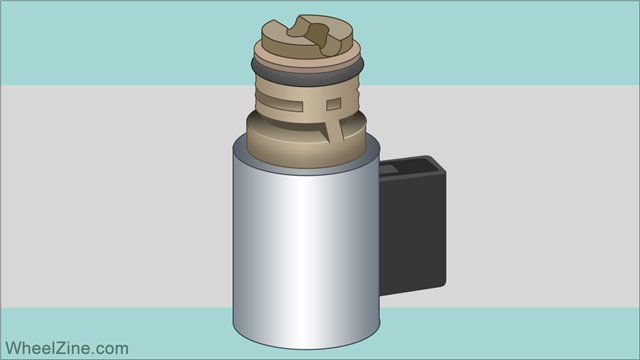

Basic Structure of a Transmission Control Solenoid

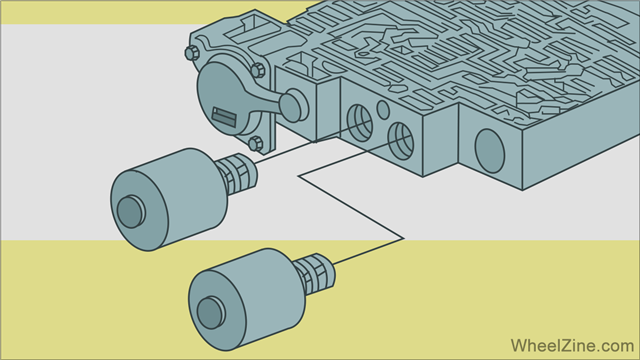

A transmission control solenoid is located in the valve body in the ‘transmission control unit (TCU) of a system. It can be seen after removing the transmission pan attached to the valve body. Generally, multiple solenoids are used in a system, and each has color-coded wires for ease of identification and replacement.

What Does a Transmission Control Solenoid Do?

Transmission control solenoids control the flow of transmission fluids into various compartments in the transmission unit, to carry out the engaging or disengaging of gear sets, clutches, and brake bands. This transmission fluid is responsible for generating the required pressure, and generates enough force to carry out these actions. The shift quality is affected with the pressure applied by this fluid. If the pressure is too high, the shifting is harsh, whereas, if it is too low, the clutch overheats. These solenoids are controlled electronically by micro-controllers, which process the information received from the various sensors located at different locations, and send appropriate signals.

Basic Components

Valve Plunger

The plunger is nothing but a bar made up of ferrous material. It is precisely machined for better linear movement, to provide accurate passage for transmission fluids

Lead Wires

Lead wires are connected at the end of the solenoid. The solenoid coils get electric current supply through these wires. They may be color coded or monochrome.

Solenoid Coils

In simple terms, solenoid coils convert electrical energy into mechanical energy (linear motion of the plunger). The coil wire is generally copper or aluminum. It is wrapped around a spool-like frame that houses the plunger.

Seals

Solenoid valve seals are located at the plunger end. They ensure wear-free movement of the plunger, and provide leakage of transmission fluid (which is under pressure). The seal material may be metallic or rubber, and must be chemically compatible with the transmission fluid.

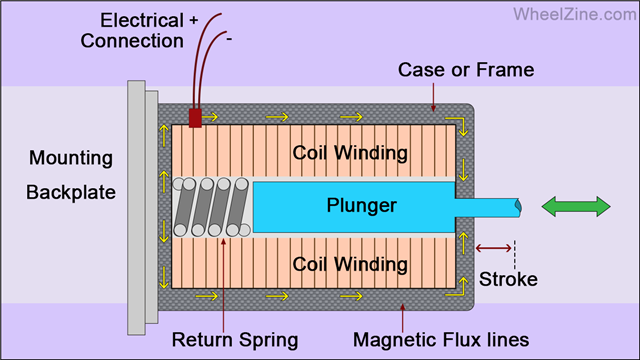

How Does It Work?

The solenoid consists of a spring-loaded plunger with a looped coil of wire wrapped around it. The solenoid may be normally open or normally closed. When the wire is energized with flowing current, magnetic flux is generated, and the plunger is acted upon against the spring force. So, a normally open solenoid closes when the wire is energized, and vice-versa. The plunger returns back to its normal position once the wire is de-energized.

Types

Variable Force Solenoid

Variable force solenoids can control the pressure in proportion (direct or inverse) to the input signal (in the form of current or voltage) from the controller.

On-Off Solenoid

On-off solenoids have defined plunger positions. When the coil is energized, the plunger moves to the other position by means of the magnetic force. The final position is defined as per the design requirements.

Pulse-Width Modulated Solenoid

A pulse-width modulation is a signal that is switched on and off at a specific frequency for a specific amount of time. In every cycle, the signal is switched on for 50% of the time.

Malfunctions and the Causes

When a control solenoid malfunctions, the primary effect is seen on the shifting quality. There might occur over-shifting, incomplete shifting, or erratic shifting of speeds.

The causes of malfunctions may be purely mechanical, purely electrical, or both. A stuck plunger is a common problem these units face. This happens mainly due to the contamination caused in the transmission fluid. The contaminants may cause extra friction, leading to fluctuating pressures and rough movements. The other cause that commonly occurs is the shorting out of the coil winding. In case of such failures, the micro-controller controlling the electrical circuit indicates the check engine light for the driver.

Some Well-known Manufacturers

- BorgWarner

- Eaton

- Bosch

- Delphi

- Hilite Industries

- TLX Technologies